Brand: Onew

Product origin: China

Delivery time: 60 Days From Receipt Of Purchase Order

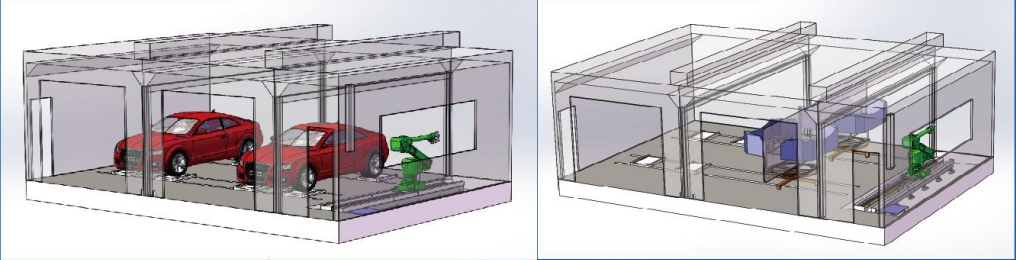

ONEW PaintGo® Intelligent Refinish Spray Painting Robotic System is a highly automatically spray painting system for automobile maintenance refinish. It can be integrated as a small painting production line into the spray booth of car repair shop. The " Composite Spray booth " process mode is composed of painting room and baking room to achieve the effect of painting and baking separation, division of labor and cooperation, and effectively improve the work efficiency.

ONEW PaintGo® Intelligent Refinish Spray Painting Robotic System has eight technical features, which can adapt to a variety of painting scenes and the existing working environment.

Seven axis spray robot, flexible and reliable

Automatic spray gun, efficient operation

Adaption to the painting process of the whole vehicle and the components

Double rotary table and four parts are sprayed together, with high efficiency

Suitable for independent spraying room and assembly line spraying

"3D cloud recognition " technology makes the production process more accurate and smoother

Automatic paint cartridge clip, providing customers with integrated service of mixing, filling, washing, delivery and spraying

The globally shared work order system automatically imports the vehicle work order information into the terminal through the global network, automatically summarizes and analyzes after the painting, and makes the refinish painting data flow and transparent

With the rapid development of machine vision, machine learning and artificial intelligence, the refinish painting industry has ushered in an opportunity for innovation. The pain points of traditional refinish painting business have been improved with high quality, efficiency and scale effect by virtue of digital technology. The key to the success of future refinish painting industry reform is to use Al technology and complete business model based on the intelligent spray robot.

Effectiveness evaluation

Assessment of the production capacity of the process mode of " Composite Spray booth " of PaintGo intelligent spray robot for automobile refinish painting:

Disassembling car parts (bumper/door panel/wing plate/front cover/rear cover) 10 heats per shift (8h/shift, 40min/heat) 4 plates per heat, up to 40 pieces per day Single shift mode/month>800 pieces Double shift mode/month>1600 pieces | On-car parts (front and rear door panels and fenders on one side of the body) 8 heats per shift (8h/shift, 60min/ heat) 2 plates per heat, up to 16 pieces per day Single shift mode/month>400 pieces Double shift mode/month>800 pieces |

Artificial intelligence improves brand reputation

The PaintGo intelligent spray robot system for automobile maintenance matches the best painting process through continuous learning and database accumulation, and instantly delivers the "best painting master" through cloud database sharing, so as to improve the brand's reputation for after-sales service.

Alternative manual spray painting

The use of PaintGo intelligent spray robot system for automobile maintenance can make the refinish painting work more friendly and replace the traditional manual spray painting method

The system standardization has low comprehensive cost and expanded scale

The intelligent spray robot has high stability and reliability, can work continuously, multiply or replace manual spray painting; Reduce rework rate; The 24-hour non-stop operation can centralize the processing of a large number of workpieces, increase the business volume, and double the benefits. Intensive production can also realize the centralized treatment of pollutants and solve the emission problem.

More standardized processes and simpler management

The intelligent digital work order system assists the order distribution and tracking system, make the painting service process information more transparency and efficient.

User Cases:

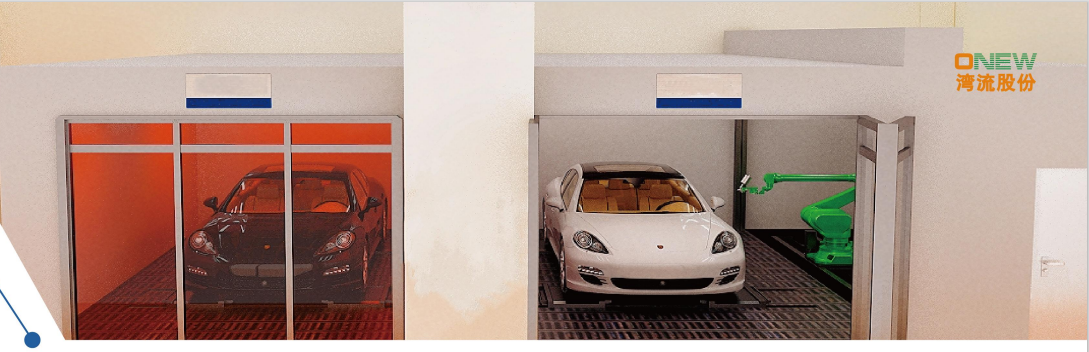

Show Case 1: Porsche Service Centre

Location : Porsche Service Centre Longgang, Shenzhen, Guangdong, China

Type of spray booth: traditional standard spray booth(spray baking integrated)

Start up date: 2022.1

Monthly production capacity: 800 pieces/set/month

Show Case 2: NextEV Service Center(Electric Vehicle)

Location: NextEV Service Center (Huangjinkou Car Repair Shop), Wuhan, Hubei, China

Type of spray booth: child and mother booth (separated by spraying and baking)

Start up date: February 2022.7

Monthly production capacity: 1000 pieces/set/month

"It brings us a stable and tirelessly paint master", says our customer.

PRICE

Ex-Factory Wuhan , China

WARRANTY

One Year Warranty Lifetime Software License validity

PAYMENT TERMS

50% Advance Payment against confirmed order

Balance before dispatch.

DISPATCH SCHEDULE

Within 60 Days from receipt of Purchase Order

INSTALLATION & TRAINING

Installation and Training through On-Line support.

For on-site, charges will be Extra.

EXPORT WORTHY PACKAGING

Inclusive