Brand: ONEW-310

Product origin: China

Delivery time: 45 Days after Confirm Order

Onew-310 spraying operation training simulator is an augmented reality visual spray painting simulation with independent intellectual property rights. The patent number is zl201830675031.6. It applies low delay and efficient acquisition technology and accurate optical spatial positioning technology to solve the problems of traditional car spray painting training and enable trainers to feel the real spraying process, The efficient training of spraying skills is carried out in a highly simulated simulation environment.

ONEW-310 Car Spray Painting Training Simulator

Features:

1. Virtual car spray painting training course.

2. Realtime spray gun tracking.

3. Paint fluid mechanics simulation

4. Playback system for better review each painting process.

5. Objective index evaluation method to score a paint

6. Paint defect supported.

7. Real Mixed Reality simulated car door.

8. Teacher and students control system.

According to statistics, using onew-310 car spray painting training simulator can greatly save the training cost, and save at least 50% of the materials and resources consumed in the training. This series of simulators has the advantages of environmental protection, energy saving, integration of painting operation skill training and evaluation, and solves the problems of great difficulty and high cost in traditional spraying training. It is an advanced solution for training spraying engineers.

This series of products are independently developed by the company, have independent intellectual property rights, and have national invention patents, national computer software copyright and other certificates.

The trainers feel the real car spray painting process and train efficiently in a highly simulated environment.

Characteristic:

1. Practical and efficient

* Rapid improvement of spraying skills

2. Innovative technology

* iMotionCap -- Precise positioning technology

* iTrue -- real spray modeling technology

3. Energy efficiency and environment friendly

* No oil paint or plate consumption

* No dust or air pollution

* No chemical or optical pollution

4. Evaluable training results

* Real-time visible control feedback

* Real-time guidance and detection of spraying

* Real-time assessment of trainers' skills

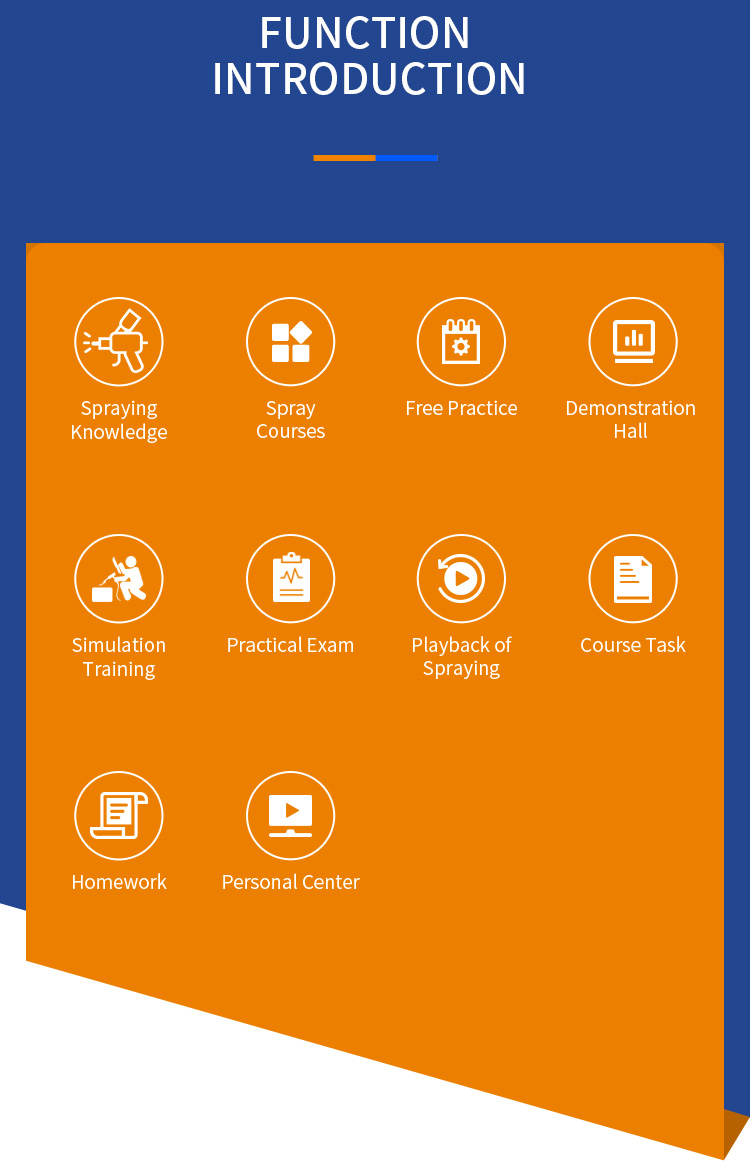

Function introduction:

1. Spraying knowledge

2. Spray courses

3. Free practice

4. Situational training

5. Demonstration hall

6. Course task

7. Homework

8. Practical exam

9. Playback of spraying

10 Personal center